TAROX Brake Kit – Replacement Rotors

€538.80 – €1,386.00 incl. VAT

- Direct replacement for worn discs

- Use your existing alloy bells

- CNC machined from billet steel

- Choice of facings available

These rotors are direct replacements for your worn out discs and will fit straight to your existing TAROX alloy bells. You will receive a pair of handed rotors with specific cooling features for the left and right side of the axle. So that we can manufacture the correct rotors we will require the part number and batch date which are machined into the alloy bells. If you need help identifying your existing parts please get in touch.

All TAROX billet discs are made to order at our facility in Italy and are available with the following facings:

- F2000 – Long curved grooves

- Sport Japan – drilled and grooved

- C83 – short straight grooves

- D95 – drilled only

- ZERO – plain braking surface

Because of this we ask that you allow 2-3 weeks for delivery.

The ‘Bespoke’ way…

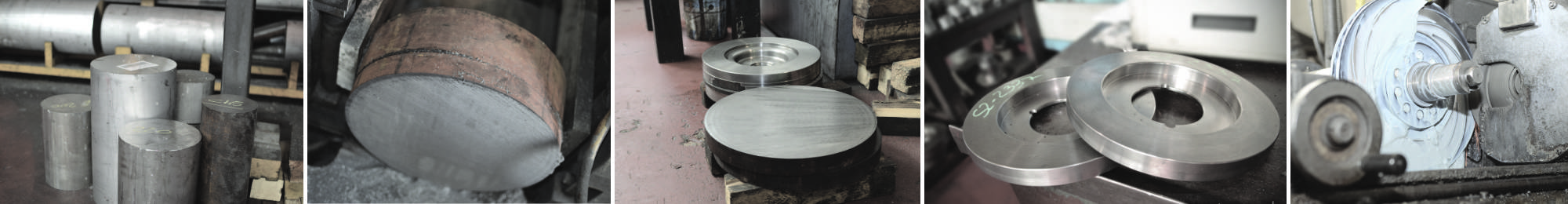

These discs are part of our special ‘Bespoke’ range which we have compiled to provide a performance solution for vehicles for which parts aren’t easily obtainable. Vehicles such as classic sports marques or modern high performance cars whose drivers seek higher levels of performance from their brake setup. All discs in the ‘Bespoke’ range are individually CNC machined from a solid piece of steel billet – they are never made in a cast. Once the billet has been machined to the required size it is heat treated and then cooled to unify the structure of the steel and improve strength and durability. This keeps the disc more stable at extreme temperatures. Characteristics such as warping, cracking, fade and knock off are all massively reduced. The longevity of the disc and pad are both extended dramatically. The toughened disc is then grooved and/or drilled as required and finally finished by hand. Each disc is manually ground to a tolerance approaching 0.015mm creating a perfectly level surface to ensure that the discs will run true. In the case of a two-piece disc, the billet rotor is then mated to a CNC machined alloy bell which has been hard anodized for protection from the elements.

The Ultimate Tensile Strength (UTS) for these discs is rated at 57kg per square mm. To put this figure into perspective, the standard for racing spec discs is usually 38kg per square mm and the CEE standard UTS is 25kg per square mm.

If you have any questions about the ‘Bespoke’ range, please feel free to contact a member of our team with your query.

| Brake System | TAROX |

|---|---|

| Disc Configuration | Rotors only |

| Quantity | 2 Discs |

DESPATCH

This website lists our entire range - it is not linked to our stock system. If you would like to check the availability of any items before ordering please call the office or get in touch via the Contact Us page.

Brake kits and Bespoke discs

All brake kits and Bespoke discs are manufactured to order at our facility in Northern Italy. Typically, we require 5-7 days to do this. Certain options, such as colour anodising, may extend the assembly time in some cases. On completion of your build, the kit will be shipped to our UK office on the next available consignment. On arrival, your kit will be despatched to your chosen delivery address within 1-2 days.

Brake discs, pads, hoses and fluid

Popular fast moving items are kept in stock and are despatched from our UK office. Orders received before 2pm will be shipped the same day. Items that are not in stock at our UK office will be shipped to the UK from our Italian facility on the next available consignment. On arrival, your order will be despatched to your chosen delivery address within 1-2 days.

DELIVERY

Once your order is ready to be despatched from the UK...

Shipping within the UK

Orders being delivered within the UK will be despatched with Parcelforce using their next day service. Text message updates are provided by Parcelforce to those customers who provide mobile phone numbers during checkout.

International Orders

International orders will be despatched using a tracked service once all applicable export paperwork has been completed. We use various couriers for worldwide shipping including TNT, FedEx, and UPS. Customers are responsible for all applicable duties and taxes. Customs, import duties (if any) and local taxes are assessed when the package arrives in your country and we are unable to advise on such matters. Please check with your local customs office for detailed information.